Dehumidifiers

Air dehumidifiers

MSHA

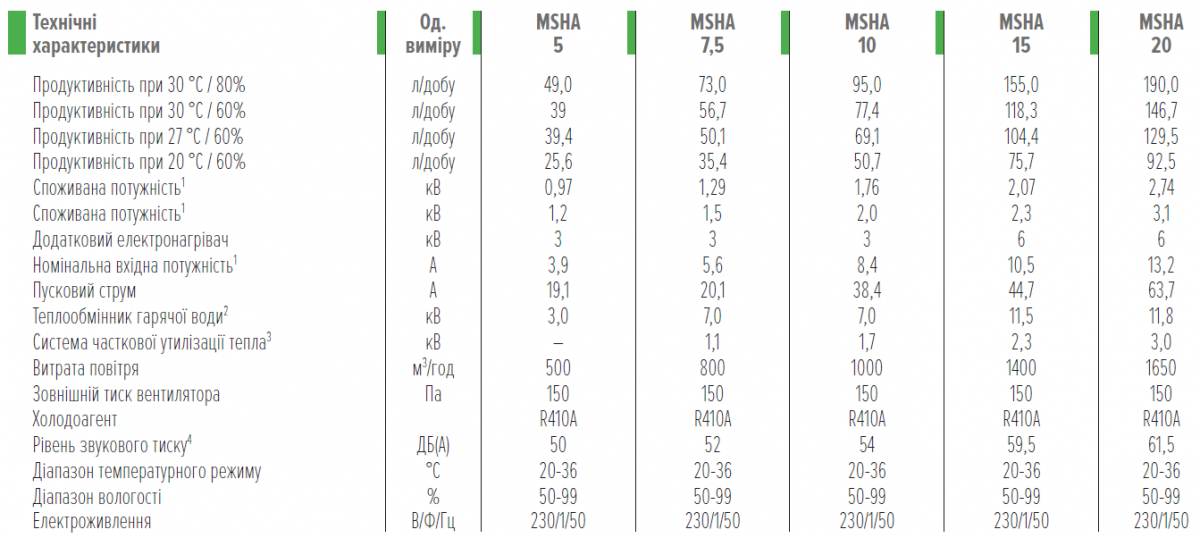

MSHA air dehumidifiers are intended for use in swimming pools, where it is necessary to carefully monitor the humidity in order to ensure a high comfort level. They are designed for installation in a suspended ceiling space or in a technical room near the pool. High-speed radial fan allows to overcome high aerodynamic resistance when laying complex systems of air ducts. The series includes 5 basic models with a capacity range from 50 to 190 l/day.

MSHA series includes 5 models with an air performance of 500 to 1900 m3/h

DEHUMIDIFYING CAPACITY: 50-190 l / day

Features

Models

COMPONENTS:

- FRAME: made from hot-galvanised thick sheet metal, painted with polyurethane powder; loadbearing frame with removable panels; all screws and rivets are made of stainless steel; color - RAL7035.

- REFRIGERATING CIRCUIT: components from the best manufacturers; welding and soldering procedures meet ICO 97/23 requirements; includes the following components: sight glass, filter drier, thermostatic expansion valve with external equalizer, Schroeder service valves, safety pressure switch; refrigerant - R410A.

- COMPRESSOR: rotary type with crankcase heater and protected from thermal overload by a thermostat in the motor winding; mounted on rubber anti-vibration supports; maintenance access via front panel.

- CONDENSER AND EVAPORATOR: made of copper tubes with aluminum fins; powder coated epoxy paint protecting from aggressive environment; heat exchangers geometry guarantees low aerodynamic resistance, which allows to reduce the fans rotation speed (and noise level); a condensate tray made of stainless steel with evaporating temperature sensor.

- FANS: radial fans are made of galvanized steel; fan wheel is statically and dynamically balanced; motor protection class - IP 54.

- AIR FILTER: disposable flat filter made of synthetic fiber without electrostatic charge; class G2 in accordance with EN 779: 2002.

- MICROPROCESSOR: all MSHA units are equipped with a microprocessor control system that supports the functions of water temperature control, frost protection, compressor protection from short cycle operation, compressor start control, fault signaling. Microprocessor control has a LED indication of operating status/failure and transmits a fault signal to the remote device.